“Small things make perfection, but perfection is no small thing.”

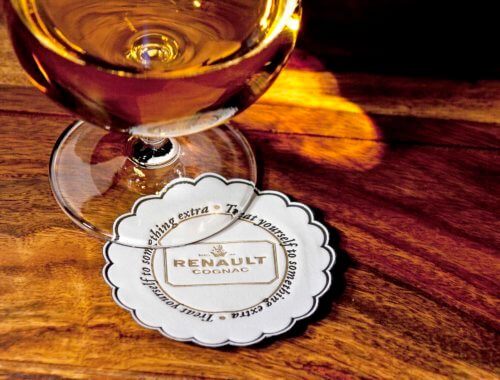

Our custom coasters add a useful detail for you and your guests that will pay off as well. Besides maximum comfort, custom made coasters from Alfred Mank also offers an ideal advertising platform and places your brand where it will really get noticed.

Alfred Mank coasters are perfect for keeping your table and bar tops dry and tidy while also effectively and inexpensively conveying your brand’s advertising message to a captivated audience.

All of our products are produced using high quality materials, from absorbent paper or soft tissue to fabric-like Airlaid or sturdy budgetboard.

We’ll expertly print your unique advertising message using either exclusive letterpress or flexographic printing methods. All of our materials and inks are approved in accordance with food safety regulations.

Available in different qualities and sizes, and using different printing methods, our drink coasters elegantly underscore your company’s image while ensuring your customers won’t spill a drop. If you are looking to order custom coasters bulk and online, please use our contact form to place your request.

CHOOSE YOUR MATERIAL:

Linclass® Airlaid Material

For our most high-quality option, choose Mank quality coasters made from Linclass® Airlaid. Velvety-soft Airlaid is almost indistinguishable from fabric, in both it’s look and feel. Produced with a paper laminate backing, it’s highly absorbent and dimensionally stable, even in high humidity. This product line will show no curling and no separation, even after extensive usage. Due to the material, we can only offer Flexoprinting, guaranteeing an elegant, beautiful surface.

Overview of features:

Available Sizes:

- Round designs: 80 – 250 mm

- Square designs: 85 x 85 mm – 150 x 150 mm

Available Printing Methods:

- Flexo printing

Minimum Quantity:

- 10,000 units

Tissue Paper Material

Next one in line, we have our Classic Tissue Paper Coasters, produced with a PE laminate backing. This product line provides the perfect combination of an elegant look with robust moisture resistance, due to its 5-to-12 thickness ply. Soft tissue wadding of various thickness ensures a high standard of absorbency. Besides both Letterpress and Flexo, we can also provide a Foil Embossed printing.

Overview of features:

Available Sizes:

- Round designs: 60 – 250 mm

- Square designs: 77 x 77 mm – 150 x 150 mm

Available Thickness:

- 5-ply

- 7-ply

- 9-ply

- 12-ply

Available Printing Methods:

- Letterpress printing

- Flexo printing

- Foil Embossed printing

Minimum Quantity

- 10,000 units

Budgetboard Material

For a combination of both durability and absorbency, we present our Budgetboard Coasters. Budgetboard is a high-quality, low-volume, absorbent paperboard which grips glasses well while absorbing liquids perfectly. Durability and absorbency make for a great choice for bars, restaurants, beer gardens, outside seating and much more. In addition to a solid grip, this product line can also absorb liquids spilled on top of them, coming up to an eight-ply thickness. Concering the printing method we offer the choice between Letterpress and Flexoprinting.

Overview of features:

Available Sizes

- Round designs: 3.5”- 4”

- Square designs: 3.5”-4”

Available Thickness

- 200 gsm

Available Printing Methods:

- Flexo printing

- Letterpress printing

Minimum Quantity

- 10,000 units

Absorbent Paper Material

For our last line of materials, we have our Absorbent Paper Coasters. Crafted to provide an unmatched absorbency level and one of the lowest volume tares, these slim design coasters are an ideal choice for your next bulk purchase at lowest price, with four available thickness models to choose from, in between 50g-200g. High levels of absorbency and low tare volume in a slim design that keep glasses and cups steady makes this variation the ideal choice for your large quantity purchase.

Overview of features:

Available Sizes

- Round designs: 2”-10”

- Square designs: 3” x 3” – 6” x 6”

Available Thickness

- 50g

- 80g

- 110g

- 200g

Available Printing Methods:

- Letterpress printing

- Flexo printing

Minimum Order:

- 10,000 units

How Can Custom Drink Coasters Help Your Advertisment?

What are the Benefits Of Custom Made Coasters?

How can I choose The Right Paper Coasters?

Which materials can I choose from for Personalized Coasters?

How Absorbent are Coasters?

How does the Paper Production Process work?

Bulk Orders Available

Sustainable Manufacturing of Our Paper Goods

About Alfred Mank - Our Customer Satisfaction Mission