At Alfred Mank, everything we create starts with paper. As young children we learn that paper comes from wood, but there’s a lot more to it. Here’s our look at what the paper production process really involves.

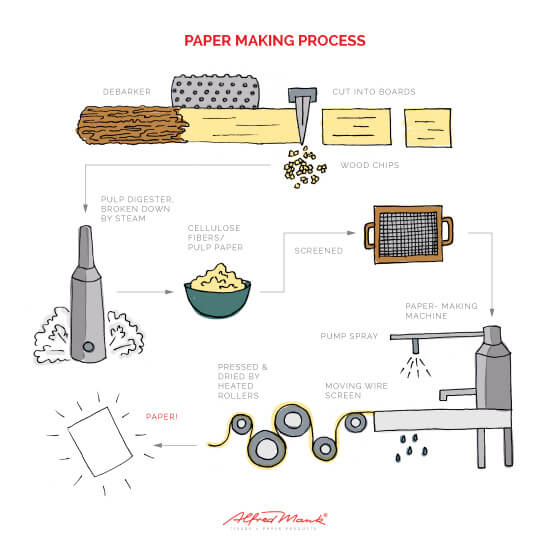

How Paper is Made

- Logs are run through a debarker which removes the bark. The logs are cut into boards for other purposes and the remaining wood is broken down into wood chips.

- Wood chips are processed by “pulp digesters” where steam and chemicals turn them into a messy stew of fibers, called paper pulp.

- Paper pulp fibers are cleaned and screened multiple times to remove chemicals, wood resins, and wood lignin.

- Paper pulp is now fed into the paper-making machine. This is done using a pump to spray a thin layer of the wet paper pulp onto a moving wire screen.

- As the pulp is carried along by the screen, the water that’s inside the pulp starts to drop away. As they become less wet, the fibers of the wood pulp become matted together and form paper.

- The paper is finally fed through a series of heated rollers which press it and dry it.

Now that you have an understanding of the basic paper production process, here’s a closer look at many of the unique materials used to produce Alfred Mank’s line of paper products and how they are made.

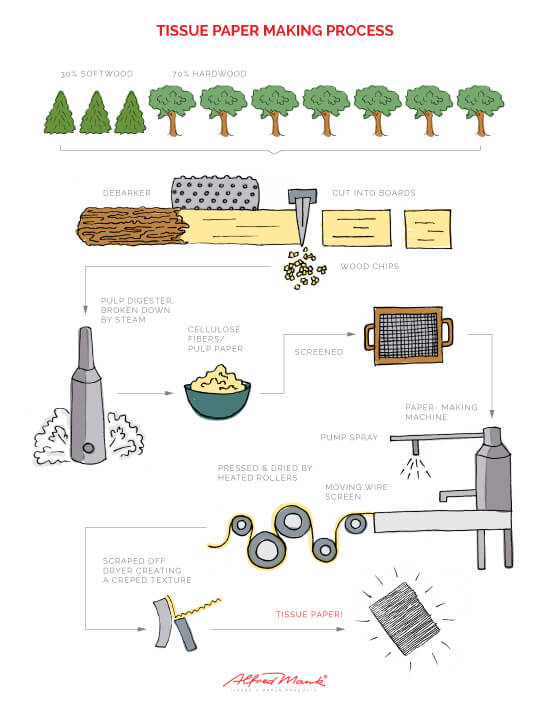

How Tissue Paper is Made

Tissue paper is a popular material used to create a number of paper products including coasters and tray doilies, as well as specialty items like plate holders, tea pot holders and egg covers.

- Tissue paper is made from a mixture of softwood and hardwood trees. Softwood trees have long fibers that easily wrap around each other, adding strength. Hardwood trees have shorter fibers that makes the paper softer. Tissue paper is generally made up of 70% hardwood and 30% softwood.

- The main difference in producing tissue paper is that it’s creped. The creping process is what makes it very soft and gives it a slightly wrinkled look.

- During creping, the paper is scraped off the dryer with a metal blade. This makes tissue paper sheets more flexible but also lowers their strength and thickness.

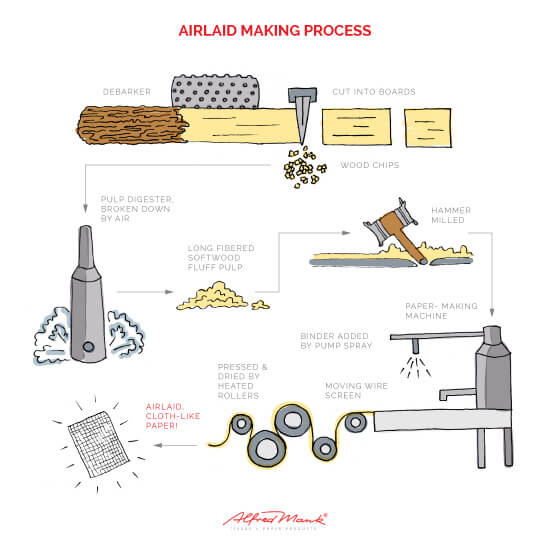

How Airlaid is Made

When you feel Airlaid, you may not think it’s paper at all. It feels almost like cloth. In fact, Airlaid is a nonwoven fabric made from fluff pulp. It’s used to create coasters, jar toppers and napkins.

- The raw material in Airlaid is long fiber softwood fluff pulp. Unlike traditional paper, it is produced using air instead of water. This adds to its absorbent properties.

- The pulp is hammer milled, freeing the fibers from each other before entering the wire of the paper machine.

- Typical Airlaid paper is made up of only 85% fiber, so a binder is added to fill the spaces, as a spray or foam, which is activated by heat.

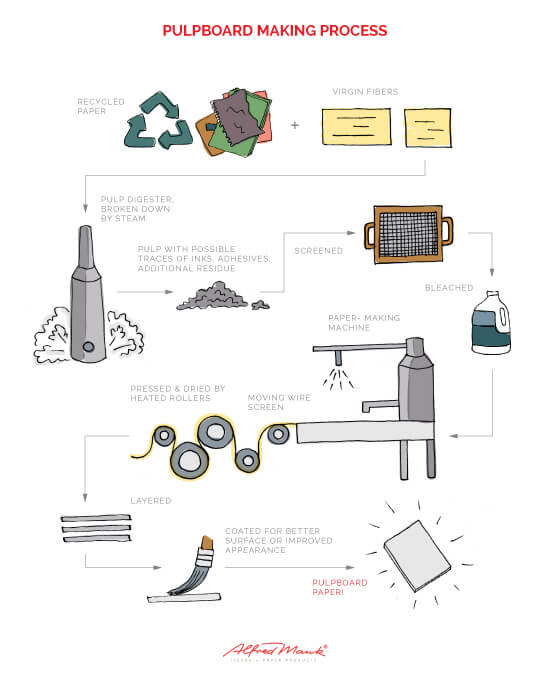

How Pulpboard is Made

Used to create the coasters and beer mats found in bars and restaurants everywhere, pulpboard can be produced in multiple thicknesses to withstand moisture and absorb condensation.

- Producing pulpboard relies heavily on utilizing recycled paper. The recycled paper is mixed with fresh, or virgin, pulp fibers in order to make new material.

- A small amount of fresh pulp is needed because recycled fiber often loses strength when reused. Virgin fibers add strength to the mixture.

- Mixed waste paper does not always go through a deinking process when creating pulpboard, so it may contain traces of inks, adhesives, and other residues which result in a grey color.

- Pulpboard can be produced as single-ply or multi-ply. When using multiple layers, each layer is treated and shaped individually, then formed together.

- Coating is added to improve the whiteness, smoothness and glossiness of pulpboard.

- Pulpboard is produced on paper machines that can handle higher grammages and plies of board.

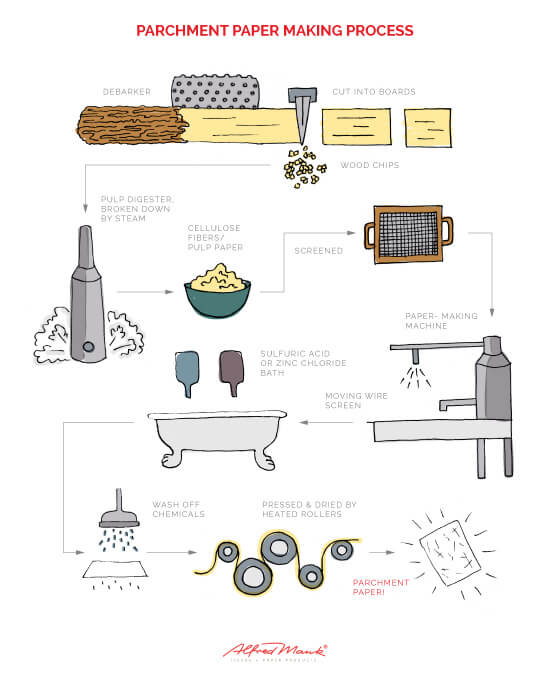

How Parchment Paper is Made

Perfect for avoiding a sticky situation, parchment paper is used to produce butter and jam covers.

- Creating parchment paper differs from the traditional paper process when sheets of paper pulp are run through a bath of sulfuric acid or zinc chloride. These chemicals partially dissolve or gelatinize the paper.

- The process is then reversed by washing away the chemicals and then drying the sheets.

- This results in paper with a higher density, stability, and heat resistance and a lower surface energy. This is why parchment paper is a perfect non-stick option.

If you have any questions about the production of Alfred Mank’s quality tissue and paper products, contact us for more information or a free product samples.

sources: How Products Are Made, International Starch Institute, The Fresh Loaf